Your Trusted Partner for Medical & Pharmaceutical Injection Molding Solutions

Sterling Healthcare Manufacturing, a Division of The Rodon Group

In the medical and pharmaceutical industries, product quality and safety are paramount. At Sterling Healthcare Manufacturing, we deliver high precision, American made cost effective plastic injection molding solutions tailored to meet the rigorous standards of these critical fields. Our expertise, combined with our modern ISO 13485 certified cleanroom facility, ensures that we maintain sterility, precision, and complete part traceability from start to finish.

In the medical and pharmaceutical industries, product quality and safety are paramount. At Sterling Healthcare Manufacturing, we deliver high precision, American made cost effective plastic injection molding solutions tailored to meet the rigorous standards of these critical fields. Our expertise, combined with our modern ISO 13485 certified cleanroom facility, ensures that we maintain sterility, precision, and complete part traceability from start to finish.

Advanced Cleanroom Manufacturing

Our state-of-the-art cleanroom is designed to minimize contamination, ensuring that every component meets stringent cleanliness and quality standards. The cleanroom environment features advanced air filtration and temperature control, supporting the production of critical components such as surgical devices, diagnostic kits, and laboratory equipment. With the flexibility to accommodate multiple injection molding presses, our setup offers scalable, cost-effective solutions.

Our state-of-the-art cleanroom is designed to minimize contamination, ensuring that every component meets stringent cleanliness and quality standards. The cleanroom environment features advanced air filtration and temperature control, supporting the production of critical components such as surgical devices, diagnostic kits, and laboratory equipment. With the flexibility to accommodate multiple injection molding presses, our setup offers scalable, cost-effective solutions.

Cleanroom Features & Capabilities:

- Modular design, scalable to fit project needs

- Configurable for Class 8 ISO certification or a white space for contamination control

- Accommodates up to 15 presses, ranging from 40 to 400 tons

- Full part traceability and compliance with FDA and ISO 9001:2015 and ISO 13485 regulations

USA Based Medical Plastic Injection Molding

Plastic injection molding is an ideal manufacturing method for medical and pharmaceutical parts, offering unmatched precision, efficiency, and cost-effectiveness. Our process and expertise ensure that each component is produced to exact specifications, with benefits that include:

- Regulatory Compliance- Made in the USA: We manufacture your components 100% in the USA and use FDA-approved medical grade materials and adhere to ISO standards, ensuring patient safety and regulatory adherence.

- High-volume Repeatability: Our capabilities ensure consistent quality for both small and large production runs, critical for sensitive medical components.

- Traceability:In the medical and pharmaceutical industries, traceability is essential we are actively and carefully monitor every step of the manufacturing process.

- Material Versatility: We offer a wide selection of engineering grade plastics with properties such as tensile strength, temperature resistance, and biocompatibility.

- Cost Efficiency: Automated and energy efficient processes reduce costs, making high quality components more accessible.

- Nimble and Secure Supply Chain: Our 100% Made in the USA manufacturing model means that you have a supply chain that is months shorter, more secure and more flexible than any off-shore option.

Key Material Options for Medical Applications

We work with a variety of high-performance medical grade thermoplastics, each offering unique benefits for specific medical and pharmaceutical uses:

We work with a variety of high-performance medical grade thermoplastics, each offering unique benefits for specific medical and pharmaceutical uses:

- Polyethylene: Durable and available in multiple forms, suitable for joint prosthetics.

- Polypropylene: Chemical and impact resistant, ideal for medical device housings.

- Polystyrene: Machinable and aesthetically versatile, often used for lab supplies.

- Polycarbonate: Impact resistant and stable, used for surgical instruments and enclosures.

- PEEK: High temperature and wear resistant, perfect for demanding medical applications.

Choosing the right material involves considering strength, regulatory compliance, and application specific operating conditions, such as sterilization requirements and chemical exposure.

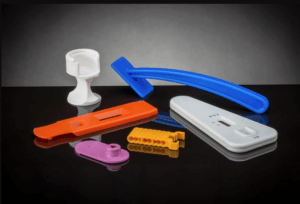

Typical Applications We Support

We have been serving the healthcare and pharmaceutical industries for decades and have the know-how to ensure the right outcome, on-spec and on-time. Our injection molding process is used to manufacture a wide range of medical and pharmaceutical components:

We have been serving the healthcare and pharmaceutical industries for decades and have the know-how to ensure the right outcome, on-spec and on-time. Our injection molding process is used to manufacture a wide range of medical and pharmaceutical components:

- Diagnostic testing kits and lateral flow cartridges

- Pharmaceutical Packaging

- Laboratory supplies like swabs, test tubes and beakers

- Medical equipment enclosures and surgical prep tools

- Custom Class 1 surgical instruments and disposable medical devices

- Dental X-ray equipment components

Want to learn more?

To see an example of our work in the medical industry, check out this case study documenting how we optimized the mold design for a polystyrene diagnostic kit. You’ll also learn about how our custom capabilities — such as machine vision inspection — guarantee quality, cost efficiency, and 100% reliability for every order we complete.

Benefit from our Turnkey Cleanroom Solution

Working with Sterling Healthcare Manufacturing means leveraging the advantages of cleanroom medical & pharmaceutical plastic injection molding without the cost of building your own. Our certified cleanroom setup enhances product quality, minimizes yield loss, and boosts efficiency, giving you the peace of mind that every part is produced in a sterile, controlled environment.

About Sterling Healthcare Manufacturing

Sterling Healthcare is a Division of Rodon the Rodon Group. Since 1956, Rodon Group has been a leader in custom plastic injection molding. Our investment in cleanroom capabilities reflects our commitment to serving the medical and pharmaceutical sectors with unmatched precision and reliability. From initial design and tooling to high volume production, we offer a full range of turnkey solutions.

Ready to Discuss Your Project? Contact us today to learn how our cleanroom and injection molding expertise can support your medical or pharmaceutical applications.

> Read More About Our Case Study