The healthcare industry is undergoing a major transformation as supply chain disruptions, rising costs, and regulatory challenges push companies to rethink their sourcing strategies. For Class I medical device manufacturers, moving production to the U.S. can improve quality, reliability, and compliance while reducing risks associated with overseas suppliers.

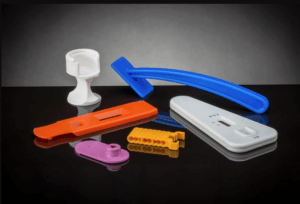

One key consideration is choosing the right plastic injection molder to support your transition. Sterling Healthcare Manufacturing, a Division of The Rodon Group, a U.S.based manufacturer with extensive experience in medical-grade plastics, offers a compelling alternative to offshore suppliers. Here’s a 10-point checklist to help you assess the benefits of reshoring your supply chain and selecting a domestic injection molder.

1. Regulatory Compliance & FDA Standards

Medical device manufacturers must meet stringent FDA and ISO 13485 requirements. A U.S.-based molder like Sterling Healthcare Manufacturing ensures compliance with these regulations, reducing the risk of non-conformance, recalls, and supply chain disruptions.

2. Supply Chain Reliability & Risk Mitigation

Global supply chain instability—caused by trade restrictions, tariffs, and transportation bottlenecks—can delay production. A domestic supply chain provides stability, reducing lead times and minimizing costly delays.

3. Quality Assurance & Process Control

A reputable U.S. molder follows strict quality control protocols, including process validation and real-time monitoring.Sterling’s advanced automation and in-line inspection processes ensure defect-free parts, which is critical for Class I medical devices.

4. Cost Control & Total Cost of Ownership (TCO)

While overseas production may seem cheaper, hidden costs such as tariffs, shipping, and quality control issues often outweigh the savings. Partnering with a U.S. supplier reduces these risks and improves long-term cost efficiency.

5. Intellectual Property (IP) Protection

Counterfeiting and IP theft are major concerns with offshore manufacturing. Working with a domestic molder ensures greater control over proprietary designs and reduces the risk of unauthorized duplication.

6. Responsiveness & Faster Time-to-Market

Communication barriers and time zone differences can slow down offshore production. A U.S.-based partner streamlines collaboration, speeds up prototyping, and reduces production cycle times.

7. Sustainable & ESG-Friendly Manufacturing

Many medical device companies prioritize sustainability and environmental responsibility. Domestic manufacturing reduces carbon footprints associated with overseas shipping and ensures compliance with U.S. environmental regulations.

8. Customization & Design Support

Sterling offers design-for-manufacturability (DFM) expertise to optimize part performance and manufacturability, helping medical device manufacturers reduce material waste and improve efficiency.

9. Scalability & High-Volume Production Capacity

With automation and robotics, domestic injection molders like Sterling can handle high-volume production while maintaining tight tolerances and repeatability—essential for medical applications.

10. Stronger Supplier Relationships & On-Site Audits

Building a strategic partnership with a domestic supplier allows for easier on-site visits, audits, and collaboration. This improves accountability and transparency throughout the production process.

The Bottom Line: Why Choose a U.S.-Based Molder Like Sterling Healthcare Manufacturing?

For Class I medical device companies looking to strengthen their supply chain, reshoring to a U.S. plastic injection molder is a strategic move. Sterling Healthcare Manufacturing provides world-class manufacturing, regulatory compliance, and cost-effective production, ensuring that your medical device components meet the highest quality and reliability standards.

Want to learn more about reshoring your healthcare supply chain? Contact Sterling Healthcare Manufacturing today to discuss your project needs.